- Standard

Tungsten copper alloy is an alloy of tungsten and copper. The copper content of common alloys is 10% ~ 50%. The alloy is made by powder metallurgy method and has good electrical and thermal conductivity, good high temperature strength and certain plasticity. At very high temperatures, such as above 3000 ° C, the copper in the alloy is liquefied and evaporated, which absorbs a lot of heat and reduces the surface temperature of the material. So this kind of material is also called metal sweating material.

Tungsten-copper composite material is a kind of two-phase structure pseudoalloy composed mainly of tungsten and copper elements, which is a metal matrix composite material. Due to the large difference in physical properties of copper and tungsten, it can not be produced by melting casting method, and powder alloy technology is generally used for production.

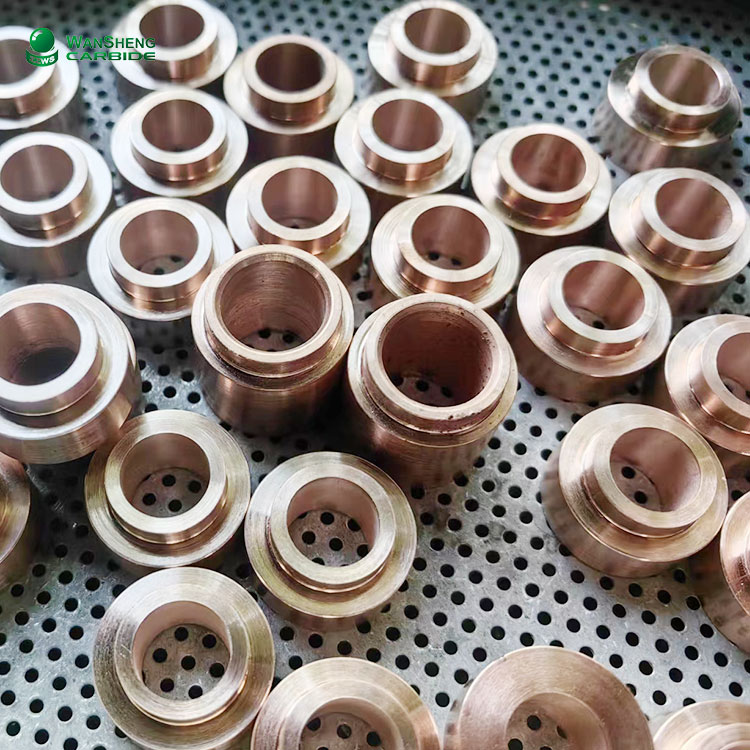

Tungsten copper alloy has a wide range of uses, most of which are used in aerospace, aviation, electronics, electricity, metallurgy, machinery, sports equipment and other industries. Secondly, it is also used to manufacture high-temperature components such as contacts of high-voltage electrical switches and rocket nozzle throat liners and tail rudders that resist arc ablation, and it is also used as electrodes for electrical processing, high-temperature molds and other occasions that require electrical and thermal conductivity and high-temperature use.

Tungsten copper alloy combines the advantages of copper and tungsten, high strength, high specific gravity, high temperature resistance, arc ablation resistance, good electrical and thermal conductivity, good processing performance. Using high quality tungsten powder and oxygen free copper powder, the application of isostatic pressing (high temperature sintering - copper infiltration), to ensure product purity and accurate ratio, fine structure, excellent performance. Good arc breaking performance, good electrical conductivity, good thermal conductivity, small thermal expansion.

EN

EN  DE

DE ES

ES FR

FR PT

PT RU

RU SV

SV TR

TR