The difference of advantages and disadvantages of titanium carbide based ceramic alloys

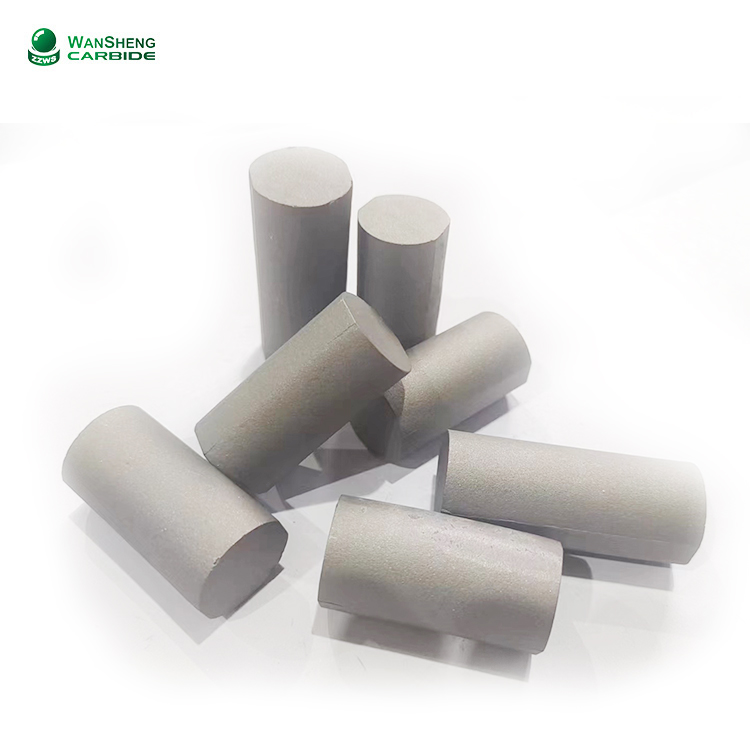

With aviation. With the development of high-end equipment manufacturing industries such as aerospace and ships, the requirements for materials are getting higher and higher. In this field, titanium-based ceramic alloy is a new type of environmentally friendly material, which is widely used because of its special properties.

(1) High hardness, strength, wear resistance: the combination of titanium metal and ceramic materials has excellent hardness, strength and wear resistance, which can be better applied to the field of aviation manufacturing.

(2) Excellent corrosion resistance: Titan-based ceramic alloy has high resistance to acids, alkalis and other chemicals, and can be used in harsh environments for a long time.

(3) Environmental protection: no harmful chemicals are used in the production of titanum-based ceramic alloys, and there is no pollution, which can be said to be a relatively environmentally friendly material.

shortcoming

(1) High cost: Titanium-based ceramic alloy manufacturing process is complex, and the material itself has a high cost, so relative to some ordinary materials, its cost is higher.

(2) Processing difficulty: titanium based ceramic alloy in the production process need to use high temperature sintering and other special processes, processing difficulty is greater.

(3) Fragile: Titanium-based ceramic alloy has high hardness, is relatively fragile, and is prone to fragmentation and other problems.

(4) Color limitation: Compared with other materials, the color of titanium-based ceramic alloys is limited to each other and cannot meet some specific needs.

EN

EN  DE

DE ES

ES FR

FR PT

PT RU

RU SV

SV TR

TR